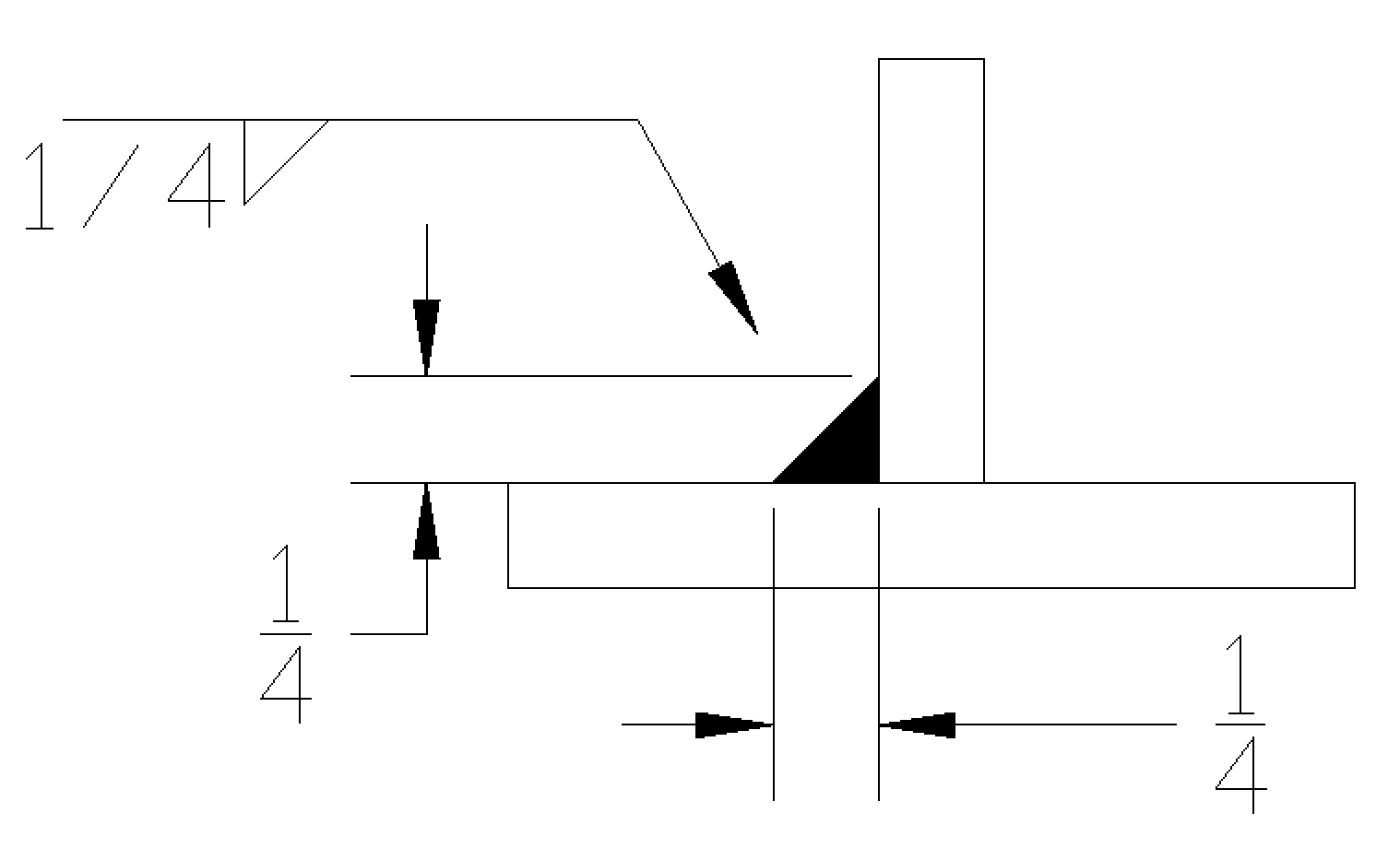

222 Joint Welding Sequence. Read welding symbols and weld various types of joints using the proper weld-.

Weld Joints And Weld Types Goodheart

Welding Joint Design Welding Symbols and Fabrication.

. Resistance spot weld symbols fig. One of the most important welding symbols is the fillet weld. Label the parts or areas of a.

Chapter 18 Activity. Welding symbols and their components are created using the same units the drawing in which they are displayed. Sketch a weld on plates in the 1G and 1F positions.

Welding Principles and Applications Fifth Edition Larry Jeffus Australia Canada Mexico Singapore Spain United Kingdom United States. Fillet welds are generally performed on a 90 degree joint of 2 perpendicular pieces of metal. 21 2022 at 1159pm.

Start studying Welding Joint Design and Welding Symbols. Continuous weld shall mean a weld which extends continuously from one end of a joint to the other. Sketch a weld on plates in the 1G and 1F positions.

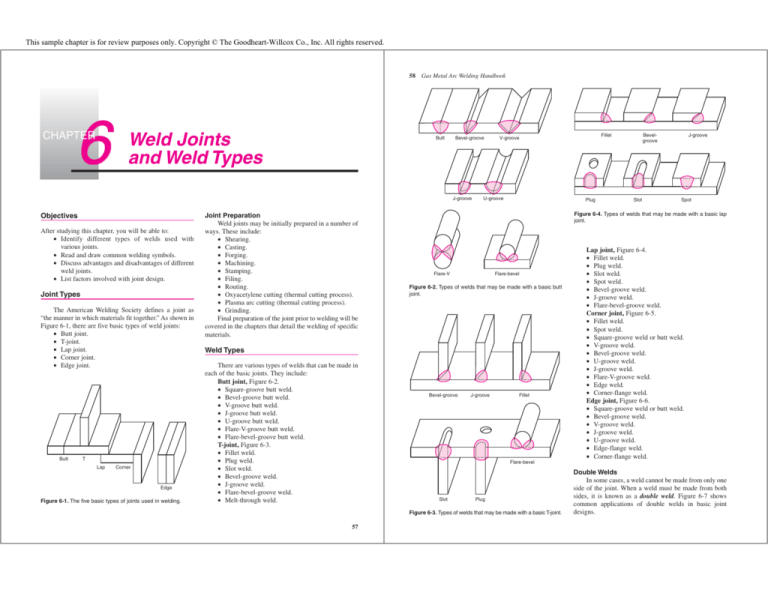

223 Weld Size and Length. A type of welding that is generally limited to thin materials high-integrity joints or small parts because of its low welding speed and high cost of equipment and materials. Basic Types of Welds.

Being one of the most popular welds in the sheet metal industry the corner joint is used on the outer edge of the piece. One addressed to the AE one for the detailer and a third. Resistance spot weld symbols shall be centered on the reference line.

Crater shall mean a depression at the termination of a weld bead. Chapter 3 Welding Joints Positions and Symbols Learning ObjectivesAfter studying this chapter you will be able to. Size of Resistance Spot Welds.

Chapter 18 welding joint design welding symbols and fabrication Written By leija Tuesday March 15 2022 Add Comment The Symbols Glossary and Appendices to this Specification are an integral part of the Specification. 3-3 have no arrow or other side significance in themselves although supplementary symbols used in con-junction with them may have such significance. A lap joint is where one plate lays on top of another plate.

Chapter 9 Welding Bonding and the Design of Permanent Joints. Chapter 18 Activity. As we know there is just so much groove design in welding.

Log in Sign up. Arc spot and seam welds Edge welds Flange welds Surfacing welds Seal welds. There are three basic types of welds.

21 2022 at 1159pm. And of The The. In addition some symbol also represents a different type of welding process in figure 3 displays the most.

Learn vocabulary terms and more with flashcards games and other study tools. Dimensions may be shown on either side of the reference line. ButtThis is a joint where two plates are butted together edge to edge.

This weld is a type of joint that comes together at right angles between two metal parts to form an L. This chapter describes the fundamentals of weld joint design including the parameters that are obtained after designing a weld joint. Welding Joint Design Welding Symbols and Fabrication.

Chapter Outline Shigleys Mechanical Engineering Design. Identify the five basic welding joints. The welded joint will occur at the edge of the top plate.

American Welding Society- CWI Welding Inspection Technology Chapter Examination 2008 146 Terms. Your assignment this week is to draw out welds on plates using 6010 and 7018 rods in different positions. This weld is an extremely common practice in fabrication and field work.

Plug and slot welds Other types of welds include. Be creative and detailed on your drawings. Up to 24 cash back Welding Process Major effect on selection of joint design Each welding process has characteristics that affect its performance Some processes are easily used in any position Others may be restricted to one or more positions Rate of travel penetration deposition rate and heat input also affect welds.

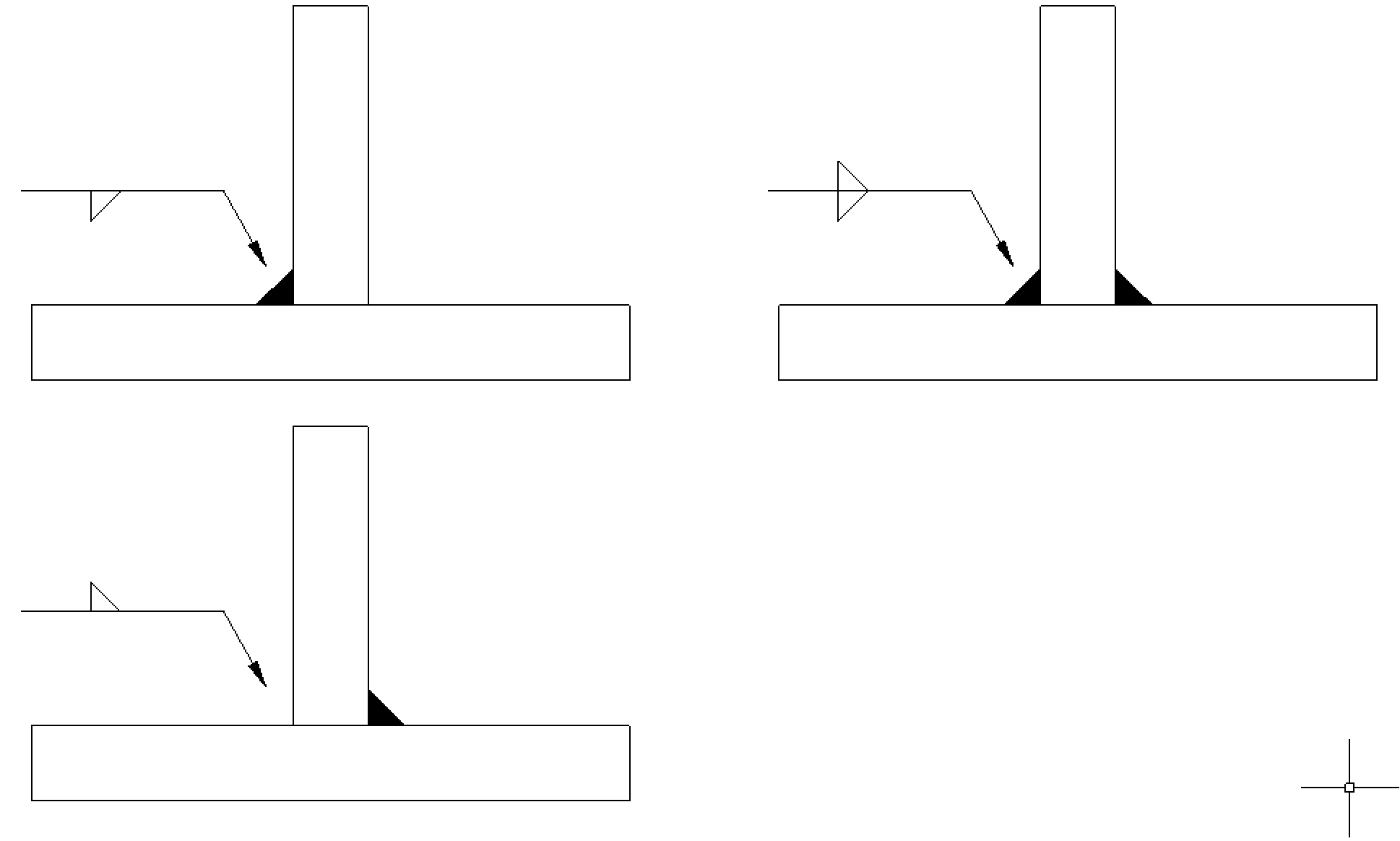

The joint design selected will of course dictate what type of weld is to be made. 11822 12122 Drawings are due on Friday Jan. This symbol is characterized by a right triangle which is the lateral shape of a real fillet weld.

Welding in chapter 7. Welding Symbols Welding symbols are defined by the American Welding Society in ANSIAWS A24 Standard Symbols for Welding Brazing and. Study Guide with Lab Manual for Jeffus Welding.

The weld joint is where two or more metal parts are. Welding Symbols Arrow side of a joint is the line. 11822 12122 Drawings are due on Friday Jan.

Be creative and detailed on your drawings. Identify and describe the various welds that may be used in each welding joint. Where the joint is essentially circular completely around the joint.

Modes of failure rigidity and stiffness loading condition welding symbol type of weld and weld joint 221 Introduction Weld joints may be subjected to variety of loads ranging from a simple tensile. Principles and Applications 8th. Principles and Applications 8th MindTap Welding 4 terms 24 months Printed Access Card.

Drawings of those joints or groups of joints in which it is especially impor-tant that the welding sequence and technique be carefully controlled to minimize shrinkage stresses and distortion shall be so noted. JS11 Joint Design Welding Symbols Student Handout for. A T joint is a joint where two metal plates are at a 90 degree angle and one of the pieces connects away from the edge.

Scarf Brazed Joint Corner Joint. This groundbreaking new text offers a complete hands-on guide to professional welding and fabrication from print reading through invoicing via small material-conserving projects that hone essential welding skills while allowing students to be creative making exercises both practical and personaland avoiding the tedium of traditional repetitive welding practices. Your assignment this week is to draw out welds on plates using 6010 and 7018 rods in different positions.

Different groove designs should have a distinct symbol to minimize the chance of making a mistake. Contract design drawings shall specify the effective weld length and for partial. Up to 24 cash back The correct joint design will then need a weld deposited to the highest quality possible at the lowest possible cost.

Fillet weld V-groove X-groove U-groove I-groove is just a few of many. Chapter 1- The Welding Inspector 6 Terms. Introduction Shigleys Mechanical Engineering Design Welding is the process of joining two pieces of metal together by hammering pressure or fusion.

Weld And Welding Symbols Plasma Welding Welding Positions Welding Machines And Other Weliding Cutting Systems Plasma Welding

Welding Symbols With Figures Paktechpoint

Symbols W3i Yahoo Search Results Metal Welding Welding Welding Tips

Understanding Welding Symbols American Welding Society Education Online

Fillet Weld Symbols Interpretation Of Metal Fab Drawings

The National Board Of Boiler And Pressure Vessel Inspectors Welding And Fabrication Metal Welding Welding Projects

Chapter 6 Welding Techniques Roadkill Customs Welding Rat Rod Chapter

0 comments

Post a Comment